Turbocharger repairs are a complex and involved process. There are many different makes and model turbochargers, and many have intricate parts internally.

Here is a list of some variations for passenger vehicles:

Journal bearing (bush type bearings) wastegated with external pneumatic actuator with/without internal electronic diverter valve

Journal bearing VNT (Variable Nozle Technology) with pneumatic actuator with/without internal electronic diverter valve

Journal bearing VNT (Variable Nozle Technology) with pneumatic actuator + Electronic Position sensor feedback

Journal bearing VNT (Variable Nozle Technology) with rotary electronic actuation

Ball bearing with pneumatic actuation with/without internal electronic diverter valve

Ball bearing with pneumatic actuation + electronic position sensor feedback with/without internal electronic diverter valve

Ball bearing VNT (Variable Nozle Technology) with pneumatic actuation

Ball bearing VNT (Variable Nozle Technology) with rotary electronic actuation

Dual boost VNT (Variable Nozle Technology) with dual bearings (ball bearing + Journal Z bearing), back to back compressor with wastegated Pneumatic and Hydraulic control (Ford Powerstroke)

Twin Sequential turbocharger, journal bearing with wastegated pneumatic control, and transition valve for turbine stage control and transition valve over compressor outlet (VW Amarok, Sprinter, Jaguar, Merc etc)

Parallel, Dual, on demand combinations with highly complex controls and calibration

Heavy Duty / Trucking:

Journal bearing (bush type bearings) non wastegated

Journal bearing (bush type bearings) wastegated with pneumatic actuation

Journal bearing (bush type bearings) wastegated with pneumatic actuation with exhaust brake

Journal bearing (bush type bearings) wastegated with pneumatic actuation + speed sensor

Journal bearing (bush type bearings) wastegated with pneumatic actuation + electronic position sensor feedback

Journal bearing (bush type bearings) VNT (Variable Nozle Technology) with Pneumatic actuation

Journal bearing (bush type bearings) VNT (Variable Nozle Technology) with Pneumatic actuation + Electronic position sensor feedback

Journal bearing (bush type bearings)VNT (Variable Nozle Technology) with Pneumatic actuation + Electronic position sensor feedback with exhaust brake

Journal bearing (bush type bearings)VNT (Variable Nozle Technology) with electronic actuation (linear or rotary control)

Ball bearing non wastegated

Ball bearing with wastegated Pneumatic actuation

Ball bearing with wastegated Pneumatic actuation + Speed sensor

Ball bearing VNT (Variable Nozle Technology) withPneumatic actuation + Speed sensor

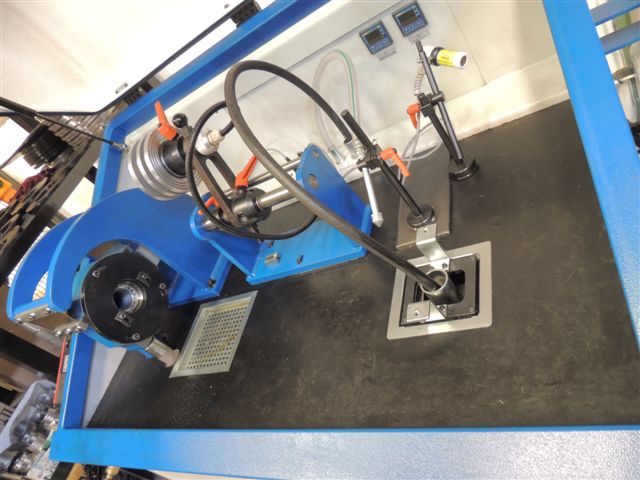

The above list of turbochargers are ever increasing in complexity, and the requirement for up to date training and in depth understanding of these components and their controls, aswell as the calibration requirements for these complex units to be able to operate to manufacturer specifications is critical. TurboDirect S.A are the only company in South Africa with the knowledge, and expertise to be able to calibrate and test these complex turbochargers in a real-time operating environment ensuring that all phases of turbo operation, including transition valve pressures, settings and VNT controls are 100% in line with the unit when it was installed onto the brand new vehicle. We own the most advanced testing and calibration equipment in South Africa, and we have manufactured our own bespoke equipment which is used together with VNT calibration and programming equipment in order to test absolutely every phase and segment of the turbochargers operation, state of balance, and oil sealing system. We are able to “dyno” any turbocharger and provide you with a print out of the performance of the unit relating to Pressure ratios, Speed, boost pressure co-efficient, flow versus rpm and plot this in a printed format to show the real time performance of the turbocharger.

Flaws in the turbocharger repair market in South Africa Specifically:

Due to the unavailability of OEM Genuine turbocharger repair spares from Garrett, BorgWarner, etc for the VNT turbochargers and electronically controlled turbochargers, the repair market is forced to source alternative parts, which land up being chinese knock-off products, which are manufactured to tolerances and materials that do not come close to the original product. TurboDirect S.A combat this by offering brand new Genuine turbochargers direct to the end user at wholesale prices. This assists in the affordability of the turbocharger and maintaining the reliability of the vehicle, with a single spend to restore the vehicles service life. Cheap Chinese repair components often require removal and re-installaton of the turbocharger numerous times after having been repaired more than once, with a bill far exceeding the cost of a new genuine turbocharger.

Service Exchange turbochargers are outlined as previously failed, second hand turbochargers having undergone a repair. There is no record of the history of these turbochargers, not the condition of the internal components, the South African market is known for grinding turbine shafts, and manufacturing oversize bearings, re-sleeving bearing and turbine housings, and using Steel type Epoxy to cover up previously damaged internal profiles on turbine and compressor housings. TurboDirect S.A are able to provide a very unique offering to combat this by ensuring a reliable and full warranted product. As the direct agents for the largest turbocharger manufacturers in the world, we have direct access to the individual components allowing us to replace any damaged component coupled together with a core exchange (not a service exchange) ensuring nothing but brand new rooting components which were factory assembled and factory balanced are installed into either approved end housings or brand new replacement end housings. At no point will yo experience a “repair” solution giving up on you due to poor workmanship or modified internal components.

As the direct agents for the Genuine brand turbochargers and repair components, in the event of a warrantee claim, should the product have been defective and a bonafide claim, it does not cost TurboDirect S.A a cent to honour this warranty as we are backed up directly by the manufacturer. Our technical expertise and factory training allows us to report back in a specific layout to the manufacturer who will honour any bonafide warranty in the space of 1-2days after receiving the report. This is something no other company in South Africa can offer.

For peace of mind and the true expert knowledge, and service - Turbodirect S.A is your turbocharger partner!