TurboDirect S.A are the leaders in turbocharger repairs in South Africa. We hold direct import agencies with the largest turbocharger manufacturers in the world, including Garrett, and BorgWarner, we also officially import Mitsubishi, IHI, and Holset turbochargers, CHRA (rotating assemblies) and repair components. We have direct access to all the manufacturers tolerances, specifications, balance outlines. Because we are the direct importers, we are able to provide these products coupled together with our services to our customers at pricing that no-one else can match.

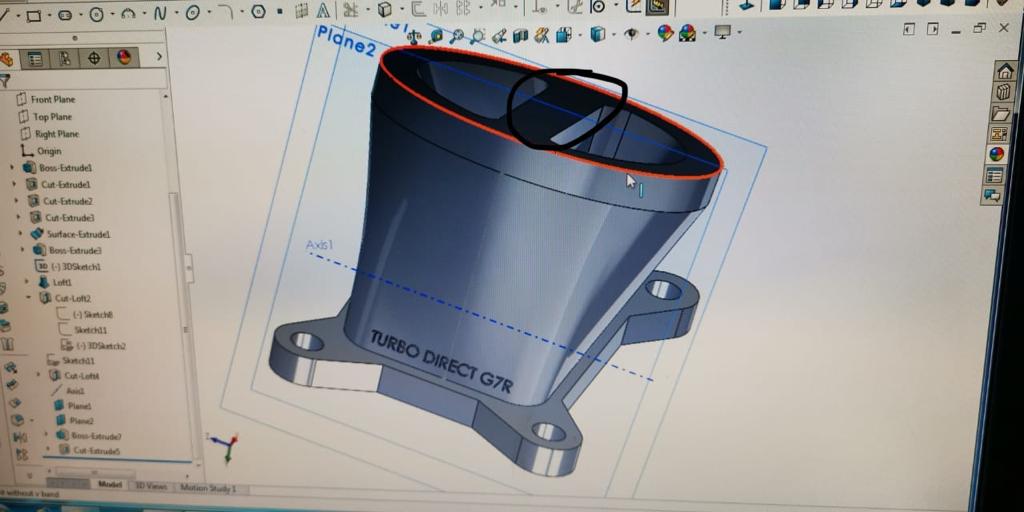

TurboDirect S.A have an in-depth engineering background and a fully equipped metallurgical laboratory which is able to analyse any material from micro to macro structure for evaluation and/or failure purposes. We are proud to be the only turbocharger company in Africa that have in-house CAD design, and 5-Axis CNC manufacturing ability, we use this equipment to manufacture our own Billet compressor wheels and export to Europe and American countries. We own the countries most advanced high speed VSR balancing equipment manufactured in Russia. We own the top of the range turbocharger flow bench and VNT calibration machine, with the ability to provide co-efficient data to draw compressor maps, and “dyno” any turbocharger against flow versus RPM. We have the ability to read, diagnose, and program any electronic actuator including HELLA, Sonceboz, Siemens, etc

We have an in-house designed and manufactured turbocharger test bench, and oil sealing pressure test machine, critical to the diagnosis and repair process. With the expertise, equipment and direct access to the manufacturers and genuine repair parts, we are able to provide the best repair solution for any make and model turbocharger, at unbeatable pricing for the South African market today.

We have a top of the line 4 wheel drive dynamometer aswell as an engine Dynamometer for the testing of any vehicle and/or engine. We own 3 Axis CNC milling, CNC lathe aswell as manual lathes, in order to provide the technical engineering services required to manufacture and repair turbochargers and related components. E.G broken studs are removed electronically through the use of CNC milling machines, and not by hand, ensuring the renewable life of an expensive earth moving or mining turbocharger.

Our technicians are trained directly at our training academy, according to the manufacturers training syllabus, exclusively available through TurboDirect S.A

All sales staff hold the highest official manufacturers training, according to the international syllabus - in order to provide a a quick and accurate pre and post sales turn around of all customers.